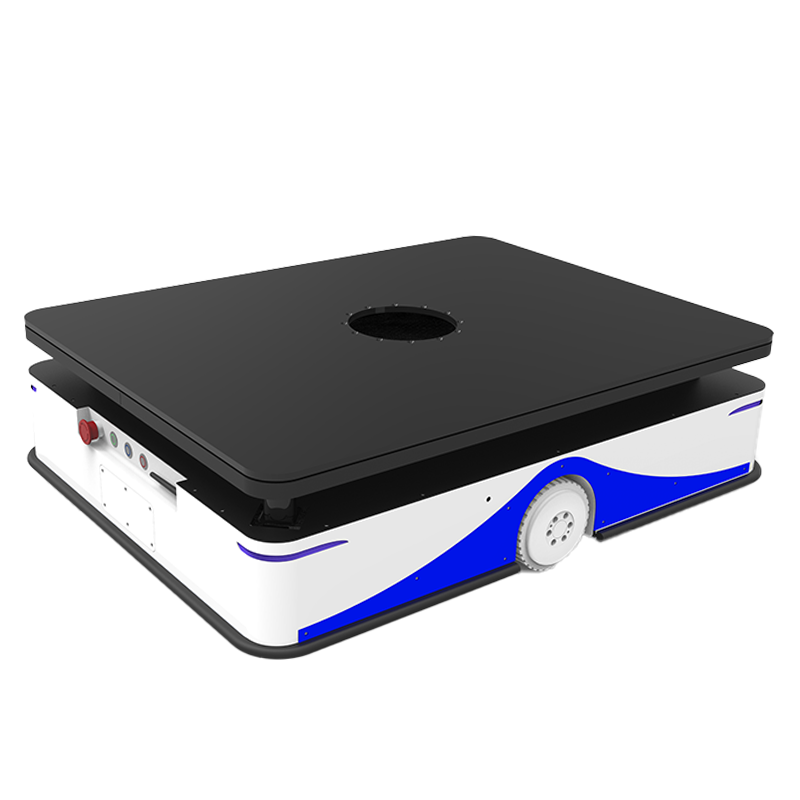

Product features:

1. The new latent jacking AGV supports dual laser navigation / QR code navigation, which is more applicable;

2. The laser navigation mode does not need to lay guide rails to transform the environment, and is compatible with laser slam navigation and reflector navigation;

3. High flexibility and simple route change to adapt to the changes of production environment of intelligent factory;

Optional configuration:

1. The transshipment goods can be equipped with shelves, jacking mechanism and rolling mechanism;

2.Optional for quota loads;

3. The endurance capacity can be matched with automatic charging pile, manual / automatic charging;

4. Support demand customization;

Product features:

1. The new latent jacking AGV supports dual laser navigation / QR code navigation, which is more applicable;

2. The laser navigation mode does not need to lay guide rails to transform the environment, and is compatible with laser slam navigation and reflector navigation;

3. High flexibility and simple route change to adapt to the changes of production environment of intelligent factory;

Optional configuration:

1. The transshipment goods can be equipped with shelves, jacking mechanism and rolling mechanism;

2.Optional for quota loads;

3. The endurance capacity can be matched with automatic charging pile, manual / automatic charging;

4. Support demand customization;

Product features:

1. The new latent jacking AGV supports dual laser navigation / QR code navigation, which is more applicable;

2. The laser navigation mode does not need to lay guide rails to transform the environment, and is compatible with laser slam navigation and reflector navigation;

3. High flexibility and simple route change to adapt to the changes of production environment of intelligent factory;

Optional configuration:

1. The transshipment goods can be equipped with shelves, jacking mechanism and rolling mechanism;

2.Optional for quota loads;

3. The endurance capacity can be matched with automatic charging pile, manual / automatic charging;

4. Support demand customization;

Product features:

1. The new latent jacking AGV supports dual laser navigation / QR code navigation, which is more applicable;

2. The laser navigation mode does not need to lay guide rails to transform the environment, and is compatible with laser slam navigation and reflector navigation;

3. High flexibility and simple route change to adapt to the changes of production environment of intelligent factory;

Optional configuration:

1. The transshipment goods can be equipped with shelves, jacking mechanism and rolling mechanism;

2.Optional for quota loads;

3. The endurance capacity can be matched with automatic charging pile, manual / automatic charging;

4. Support demand customization;

Product features:

1. The new latent jacking AGV supports dual laser navigation / QR code navigation, which is more applicable;

2. The laser navigation mode does not need to lay guide rails to transform the environment, and is compatible with laser slam navigation and reflector navigation;

3. High flexibility and simple route change to adapt to the changes of production environment of intelligent factory;

Optional configuration:

1. The transshipment goods can be equipped with shelves, jacking mechanism and rolling mechanism;

2.Optional for quota loads;

3. The endurance capacity can be matched with automatic charging pile, manual / automatic charging;

4. Support demand customization;

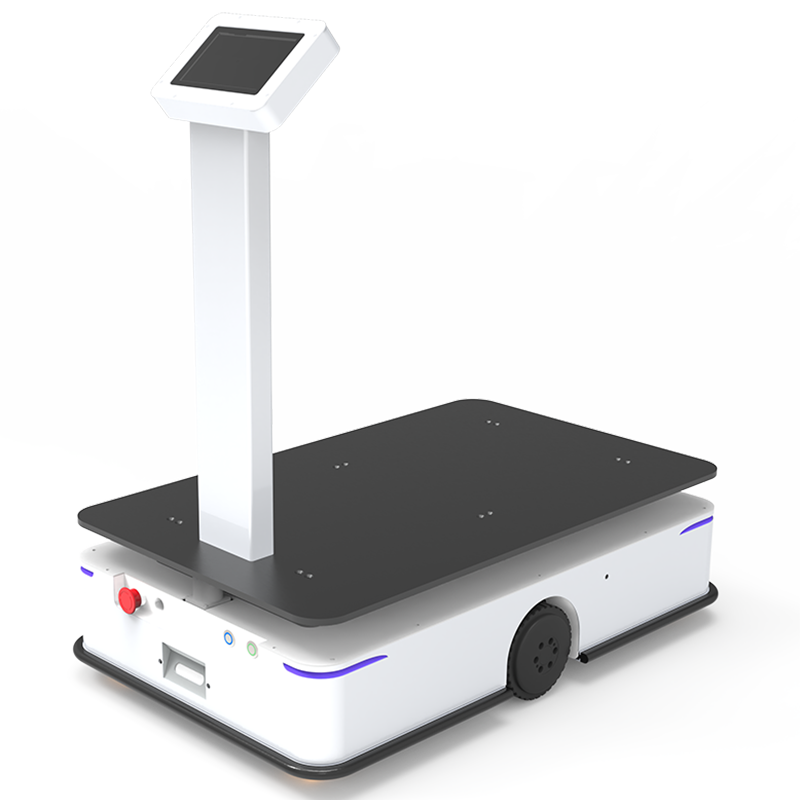

Product features:

1. Rapid deployment: automatic generation of accurate environment map without scene transformation to realize path planning and scheduling;

2. Strong expansibility: it has a general interface and can quickly carry various application function accessories;

3. Self detection: real-time feedback of the working state of the robot, with self inspection and fault detection functions;

4. Power stability: independent patent structure, the power can be positively correlated with the load within the safe range, and can be automatically adjusted;

5. Mixed driving mode: support dynamic avoidance mode and fixed line patrol mode;

6. Strong versatility: it can be used to build service robots (disinfection robot, meal delivery robot, medical robot) and industrial mobile platform AGV.